In recent days, with the news that a shipment of M141 SMAW-D anti-structure weapons have arrived in Ukraine as part of the US military aid shipments, a number of media articles and videos have been made on the subject which seem to confuse the SMAW-D with the AT-4 and even the M72. So, I thought it would be useful to take a look at the SMAW-D in a little detail.

So What is the SMAW-D?

Its official designation is ‘Rocket and Launcher, 83mm HEDP Bunker Defeat Munition (BDM), M141 (SMAW-D)’ SMAW-D stands for Shoulder-Launched Multi-Purpose Assault Weapon-Disposable. This isn’t to be confused with the Mk 153 Shoulder-Launched Multipurpose Assault Weapon used by the US Marine Corps. Those the SMAW-D did evolve from the SMAW.

The initial Mk 153 SMAW evolved from the Israeli IMI B-300. During the early-1980s McDonnell Douglas further developed the system and it entered service with the US Marine Corps as the Mk 153 in 1984. The SMAW-D shares the same warhead as the Mk 153 SMAW. The SMAW-D was originally developed by McDonnell Douglas and the design was acquired by Talley Defense Systems, whom were subsequently acquired by Norwegian company Nammo.

The Mk 153 has a reusable forward launch tube and firing mechanism which has a spotting rifle and can be mounted with an optic. The warhead element of the SMAW is attached at the rear of the launcher. The US Army was initially interested in the Mk153 but preferred a lighter, single use weapon.

In the early 1990s the US Army began the search for a disposable Shoulder-launched Multipurpose Assault Weapon. McDonnell Douglas offered a lighter, disposable version of the Mk 153, taking the Mk 153’s High Explosive, Dual Purpose warhead and pairing it with shorter burn rocket. In 1996 the US Army selected the SMAW-D, beating a Swedish design, the FFV AT8, and the Hunting Engineering LAW80. The SMAW-D entered service in 1999.

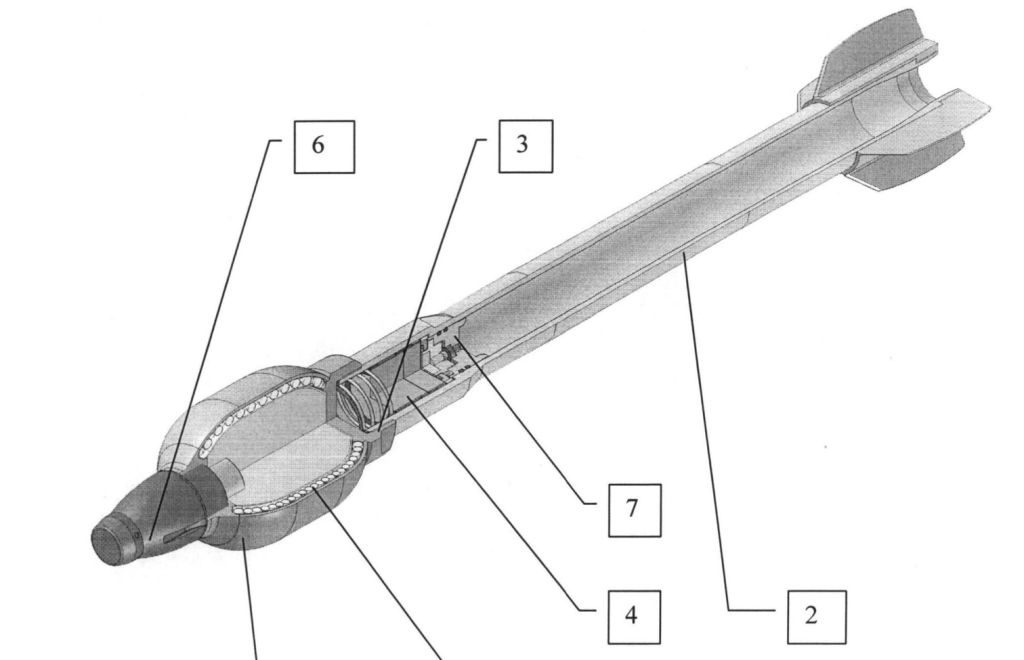

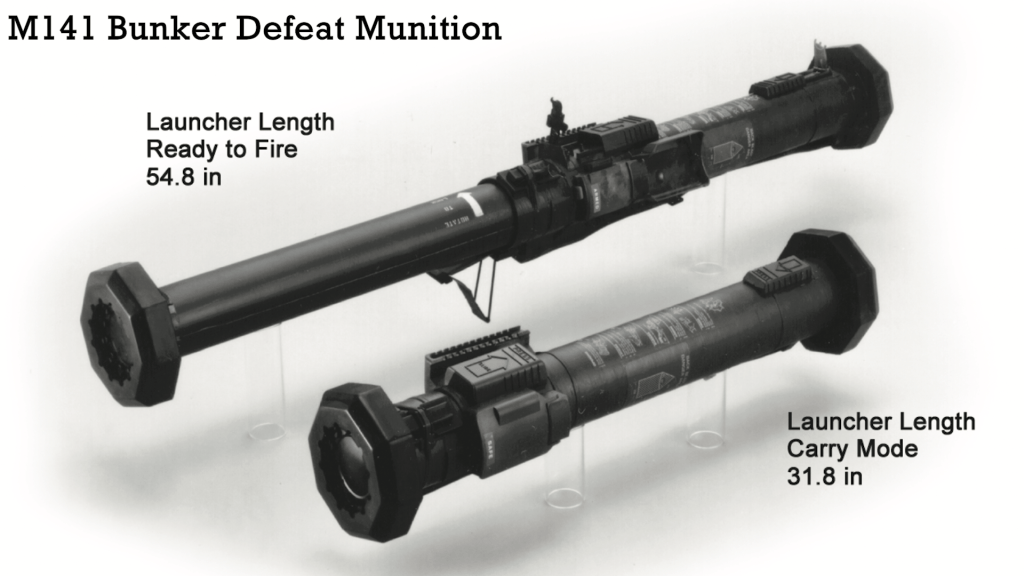

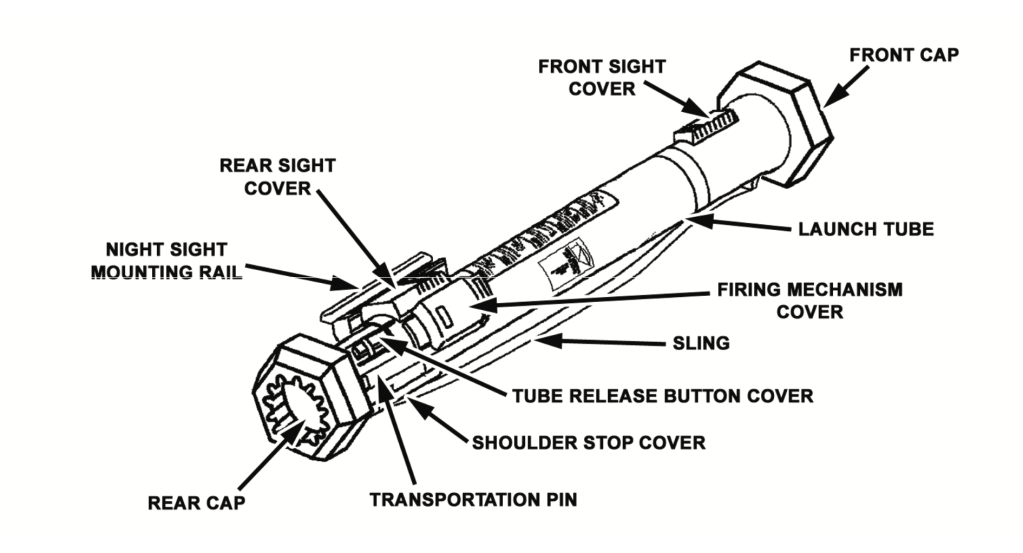

The SMAW-D is similar to the 66mm M72 in that it telescopes with the launch tube extended before firing. When collapsed it measures just under 32 inches in length but extending the inner tube gives the weapon an overall length of 55 inches. The launch tube and rocket weigh 15.7 lbs.

The tube has the firing mechanism mounted on the side under a plastic cover which when opened arms the rocket ready to fire. The weapon has front and rear iron sights for aiming. The SMAW-D can also be fitted with an AN/PVS-4 nightsight and various infrared aiming lasers for night fighting.

To fire the M141 the operator removes the locking pin from the front of the launch tube, depresses the tube release button and extends the inner tube rearward. The operator then raises the weapon onto the right shoulder, slides the front sight cover forward and then the same for the rear sight. Then opening the firing mechanism cover pivoting it forward, flush with the tube, this arms the weapon. The operator should then check the backlist area and fire when ready by depressing the safety button and then the red trigger button. The rocket is ignited by an electrical impulse sent by the firing mechanism. Once ignited the rocket burns out before it leaves the muzzle, this protects the operator.

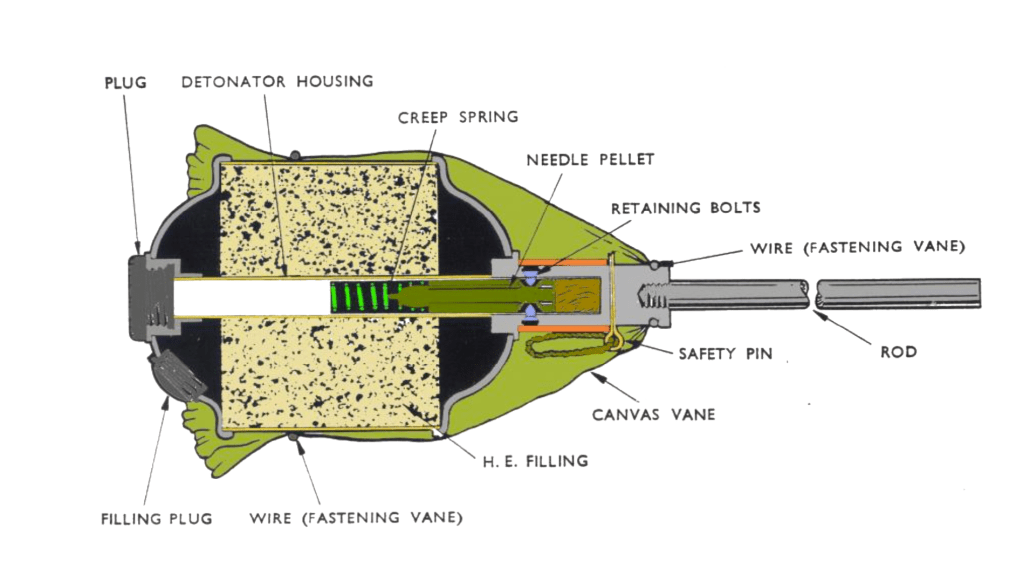

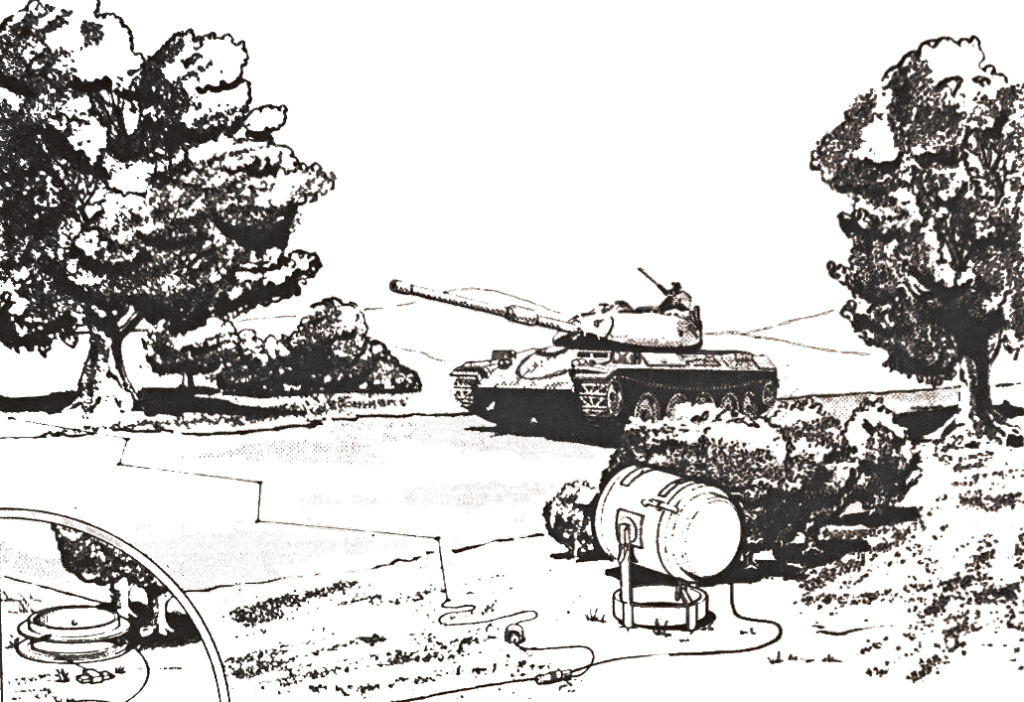

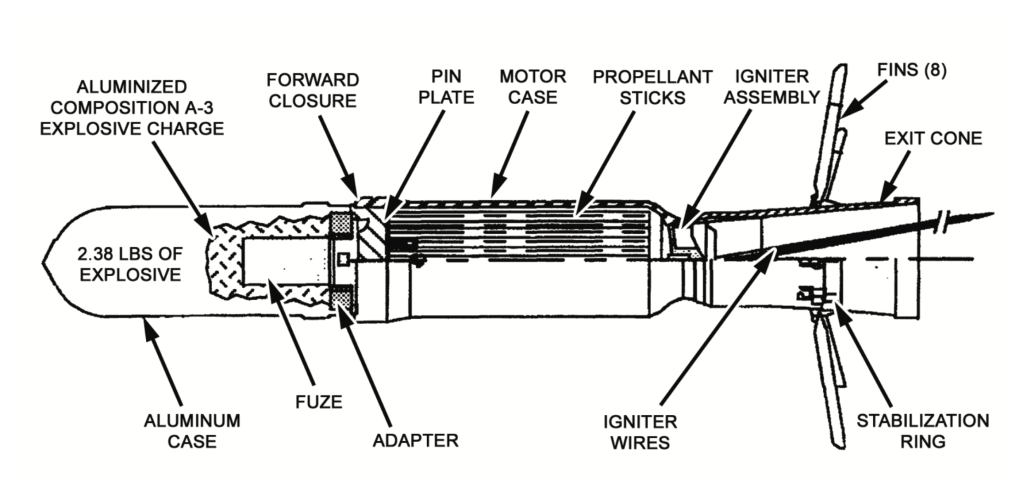

The M141 can engage targets out to 500 metres but is most effective out to 300. Its 83mm unguided, fin-stabilised round has an integral high-explosive, dual-mode warhead with 2.38 lbs of explosive. Detonation is instantaneous when impacting on a hard target, such as a brick or concrete wall, or an armored vehicle. Impact with a softer target, such as a sandbagged bunker, results in a fuze time delay that permits the rocket to penetrate into the target before warhead detonation. It can penetrate up to 200mm (8 inches) of concrete, 300mm (12 inches) of brick and 2m (6 feet 6.74 inches) of earth or sandbags. It can also perforate up to 20mm (0.8 inches) of rolled homogenous steel giving the SMAW-D the ability to take on soft and light armoured vehicles. For training at the range a 21mm sub calibre training system can be used. While the usefulness of the M141 might be questioned, as it isn’t an anti-tank weapon and could be considered more of an offensive rather than defensive weapon it would no doubt prove very useful during urban fighting, which Ukraine anticipates in the event of an invasion.

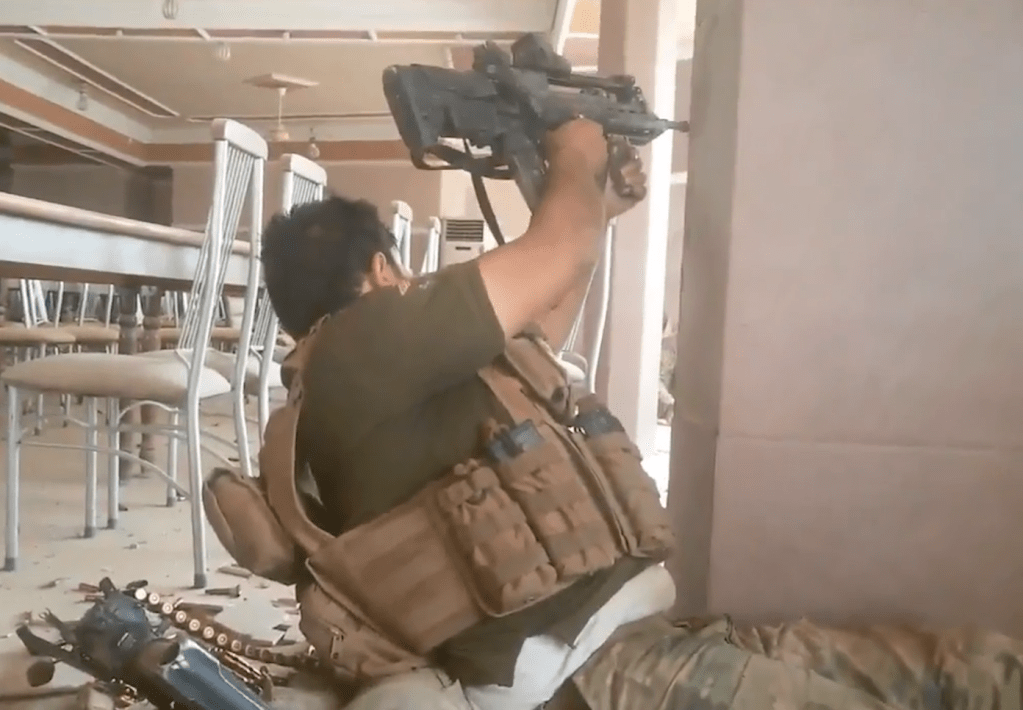

The SMAW-D saw service with the US Army during the War in Afghanistan and during the Iraq War. Some 6,000 units were initially procured, with an unknown number procured since. It remains an active part of Nammo’s product line.

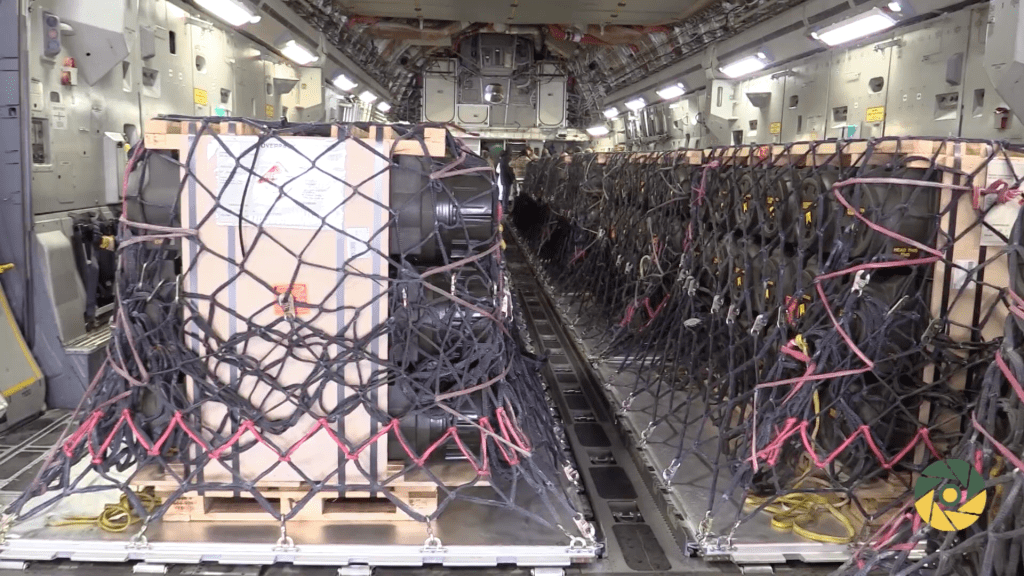

It is estimated that perhaps 100 M141 BDMs have been shipped to Ukraine so far as part of military aid, alongside small arms and ammunition, Javelin Anti-Tank Guided Missiles and NLAW anti-tank weapons from the UK. From the US Department of Defense’s packaging configuration table for the SMAW-D we know that each metal container holds one round and that 25 containers can be placed on a pallet. This appears to match up to the photos of the weapons being prepared for shipment. The Ukrainian Ministry of Defence and media have shared photographs of Ukrainian personnel training with M141s under the supervision of US troops. The training took place over two days at the 184th Training Center and the International Center for Peacekeeping and Security of the National Ground Forces Academy. These personnel will likely be tasked with then training other Ukrainian units on how to use the weapon.

M141/SMAW-D Specifications:

Length (extended/ready to fire): 1,371mm (54.8inches)

Length (closed/carry): 792mm (31.8inches)

Weight (ready to fire): 7.12 kilograms (15.7 pounds)

Rocket muzzle velocity: 217 meters per second (712 feet per second)

Rocket diameter:83mm (3.26 inches)

Minimum arming range: 15 meters

Maximum effective range: 300 meters

Maximum range: 500 meters

If you enjoyed this video and article please consider supporting our work here. We have some great perks available for Patreon Supporters – including custom stickers and early access to videos! Thank you for your support!

Bibliography:

FM 3-23.25 Shoulder-Launched Munitions, 2006, US Army

Bunker Defeat Munition (BDM), Nammo, (source)

M141 Training, Ukraine Ministry of Defence, (source)

M141 Training, Ukraine Land Forces, (source)

Thank you to Amael for sharing some of the documents and manuals used to make this video.

Footage/Imagery:

Marines fire SMAW, have a blast, USMC, (source)

Dover supports strategic partnership with Ukraine, US Air Force, (source)

Dover AFB supports US, Ukraine strategic partnership, US Air Force, (source)

Sadr City 2008 SMAW D, Gold 5 Publishing, (source)

SMAW-D (AT-4) fired in combat Sadr City, Iraq, Bowen11b, (source)