In a recent article/video we looked at the proliferation of Russia’s unusual ‘Turtle Tanks’ which are protected by ad hoc, locally fabricated counter-FPV shells. Since then we’ve gotten a good look at several more Turtle Tanks and our first look at the driver’s point of view.

Footage, filmed on 27 April, of another Russian armoured assault into Krasnohorivka shows a column of four infantry fighting vehicles with what appear t o be counter-FPV shelters following a tank with a ‘cope cage’

On the 29 April, a Ukrainian Telegram channel posted a short video of a ‘Turtle Tank’ attack in the Bakhmut direction, noting that [machine translated]: “the equipment is stupidly scalded with metal, from 5 units it was possible to destroy a tank and an armored personnel carrier. A lot of FPV was spent on one tank. Everyone laughs at their construction of barns, but in fact they work like hell.” The tank appears to have a box like shelter with a sloped forward roof over its gun and glacis. As seen in earlier videos the tank is leading a column of armoured vehicles during the assault, clearing a path for them. It appears to detonate a mine with its mine plough and retreats.

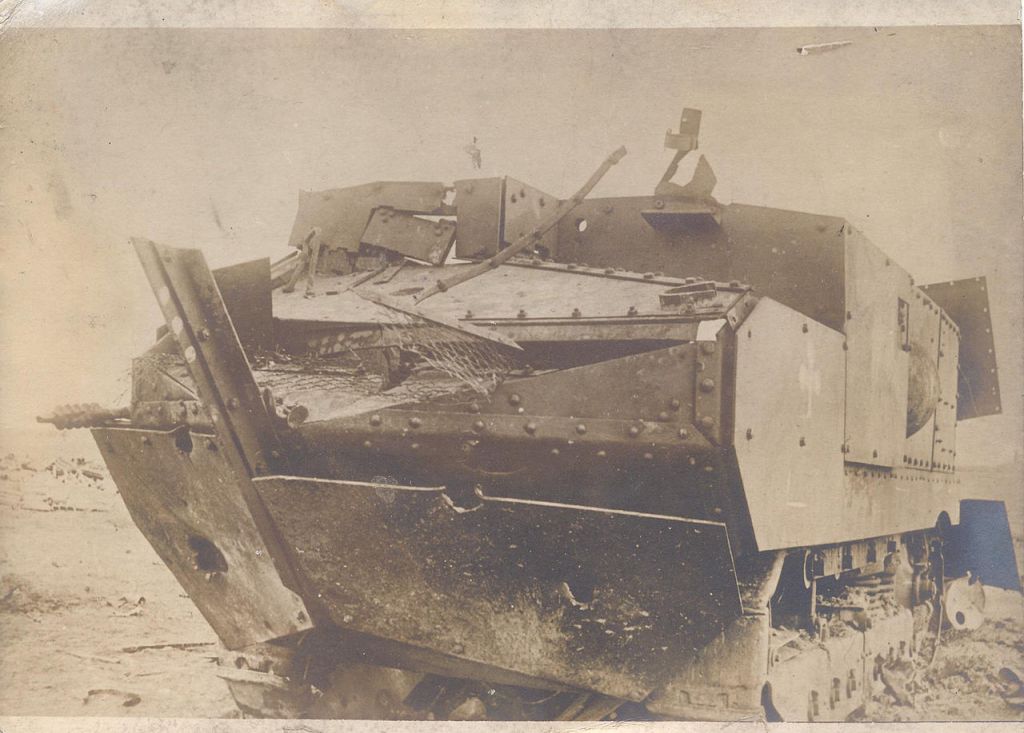

At the start of May a pair of T-62s with hybrid counter-FPV shelters were seen in photos taken by a UAV, location unconfirmed. These images illustrate the blurring of the lines between ‘cope cage’ equipped tanks and the ‘turtle tanks’. Like the earlier turtle tanks they’re fitted with EW sets & KMT-6 mine ploughs but do not have shells made entirely from sheet metal. Instead, they appear to have used chainlink and gratings, one piece of which appears to have Kontakt (explosive reactive armour (ERA) mounted. One of the vehicles appears to have been used to transport supplies. One T-62 has broken tracks, the other top damage.

Around the same time the Ukrainian 79th Air Assault Brigade shared video of Russian attacks near Novomykhailivka, in Donetsk, the footage included a brief clip of a ‘turtle tank’ with a small forward opening, camouflage over its shell frame and no sign of a mine plough or roller fitted. On 2 May, the 33rd Mechanized Brigade shared footage from thermal camera-equipped FPV drones showed a Russian tank being used to transport troops, the profile of the counter-FPV shelter is visible but the low definition of the thermal footage makes it difficult to analyse its construction. The vehicle, however, appears to be equipped with a mine plough and possibly an EW module.

Also on 2 May, Ukrainian drone fundraiser Teoyaomiquu shared a video of a Russian assault near Ivanivske which shows a pair of Russian armoured vehicles with counter-FPV shells, one of which deploys a smoke screen. The 1st Assault Battalion of the 5th Separate Assault Brigade also shared footage from the Russian assault showing the shell-equipped vehicles.

On the 5 May a short video was posted by a Russian combatant which showed an entirely enclosed MT-LB with steel plates surrounding the top of the vehicle and its wheels. It also has an additional mesh roof cover to add additional top protection. Two cutouts in the side and one in the front for the driver also have mesh covers to give some visibility. On the same day video of a destroyed BTR-MDM which had been encased in a counter-FPV shelter was shared, showing the rear of the vehicle enclosed.

Perhaps the most striking evolution of the ‘Turtle Tank’ appeared on 5 May, a tank completely enclosed except for a small gap at the front. Protective grills made from cages completely cover the outer metal sheets of the counter-FPV shell. One Russian telegram channel likened it to a rolling ‘poultry farm’. The vehicle also has a KMT-7 mine roller. Additional video of the porcupine-like tank gives us the first look at what it is like driving one of these ‘turtle tanks’, with his hatch open the driver has an almost clear view ahead (apart from the solid awning above him and the partial grill cage protection to his front) but no view to the left or right front quarters of the tank.

Several days later footage from inside what appears to be the same tank shows the driver steering by video monitor. The readout on the monitor suggests the video’s resolution is 4K H.265 but the field of view appears limited, with the camera seemingly positioned on the shell’s awning looking down between the KMT-7’s two rollers. The system used is from Russian automotive accessory company Eplutus and appears to be one of their rear view camera monitors.

Another piece of UAV footage shows another ‘turtle tank’ with a much boxier shell. It again has all of the major features seen in earlier examples: a sheet metal shell which encloses most of the top part of tank, a set of mine rollers and a EW jammer module on the roof. Some sources suggest the footage was filmed near Bilohorivka, in Luhansk. It’s unclear when the footage was filmed but the vehicle appears stationary with access grates to the tank’s rear deck left open.

The 7 May saw evidence of the proliferation of t he ‘turtle tank’ concept with Russian social media sharing photographs of a ‘Turtle Tank’ fabricated by the Russian 40th Naval Infantry Brigade, these indicate that the concept is continuing to proliferated, perhaps without any central influence. The tank is encased in a counter-FPV shelter made up of three large metal sheets, a poorly fabricated angled roof which slopes at the rear with a flat top and a wire mesh slopping front piece. Additionally on the floor there appears to be a chair curtain similar to those seen on other ‘turtle tanks’. The rear has an extended deck and appears to be enclosed. A skirt of Kontakt-1 ERA has been roughly added around the skirt. As with other Turtle Tanks the ‘V Turtle’ is equipped with what appears to be an RP-377 electronic warfare jammer. It also has a KMT-6 mine plough fitted. A large white V has been painted on the sides of the shell and Russian flag rings added to the barrel.

On 10 May, footage of an FPV drone attacking an immobilised ‘turtle tank’ emerged. The tank is again enclosed by a counter-FPV shell and has a mine plough. The feed from the drone also suffers from some interference as it approaches the vehicle suggesting that an EW module may be present nearby, perhaps aboard the tank. However, it appears that a mine has damaged the tank’s tracks and the vehicle has been abandoned allowing an FPV to attack via an open rear hatch. The footage was reportedly filmed during the first day of the new Russian offensive towards Kharkiv. This again shows that not only is the concept proliferating but also that the ‘turtle tanks’ are still vulnerable to conventional anti-tank weapons like mines.

Also on the 10 May, the Russian military channel, Large Caliber Trouble, shared a photo of the porcupine turtle tank which had been damaged by FPV strikes showing the cage bars bent and some holes in the counter-FPV shell. The post claims that the tank was “attacked by 40 kamikazes, [but] thanks to electronic warfare, most of them fell and only 8 FPVs were able to cause damage.” The condition of the vehicle after the engagement is unknown. The suggestion that a large number of FPVs attacked the tank supports the earlier Ukrainian comments about ‘a lot of FPV [being] spent on one tank.’

A key question is how can the Turtle Tanks be defeated? Basically just like any other tank can be: anti-tank guided missiles with tandem warheads, dense mines belts, direct hits by artillery, use of multiple FPV drones to damage and breach the shell with additional drones to exploit gaps made.

We will probably see further proliferation of the ‘turtle tanks’ in coming weeks but with time the Ukrainians will probably find ways to engage these protected tanks more effectively, as is so common in war there will probably be a continued evolution of measure and counter-measure.

Support Us: If you enjoyed this video and article please consider supporting our work here. We have some great perks available for Patreon Supporters – including early access to custom stickers and early access to videos! Thank you for your support!